Big One slabs, in sizes 1000×3000 mm and Full Size, are carefully packaged in wood crates that can be stacked and are specifically designed for damage- free delivery.

Big One, size 1000×1000, is packaged in die cut cardboard sheets placed on stackable pallets.

When Full Size slabs are shipped in containers, space, volume and cost are optimized by using TWIN BED (a stackable double crate).

This packaging has been purposefully designed for overseas shipments of

FULL SIZE slabs.

BIG ONE 3+, BIG ONE 6 and BIG ONE 7 size 1000x3000 and FULL SIZE, are carefully packaged on wooden crates that can be overlapped, suitably designed for a damage-free delivery.

A TWIN BED crate is used to transport FULL SIZE slabs. This crate has been specially designed to hold two rows of slabs side by side.

Handling and storage

Big One 3+, in the size 1000×3000 mm and FULL SIZE, can be easily lifted and vertically positioned by a single operator and can be handled by two operators.Big One 6, Big One 7 need two operators for all handling operations. Always work keeping a correct posture, avoiding excessive stresses in the lumbar area; wear suitable gloves for a better grip and to avoid abrasions.

Palletized package handling by fork lifts

To lift and move crates of slabs 1000x3000 mm or Full Size, using fork lifts or yard cranes, it is important to get the package in the long side, caring to position in its center, extending the forks as much as possible as they have to grip all through the pallet depth.

If the pallet is lifted from the short side, or whenever the TWIN BED crate is moved, as it could happen while unloading from a container, min. 2.5-m long forks shall be used for a correct product handling.

Manual handling and storage

1) Position the package close to the surface to be coated. Lift the slab from the long side till positioning it vertically.

2) Handle the slab with the aid of a second operator, keeping it always perpendicular to the ground, without bending and protecting corners against accidental impacts.

3) Lay the slab gently on the long side, keeping it slightly sloped and caring to arrange it on soft material or suitably spaced wooden strips.

4) Overlap several slabs horizontally, making sure the surfaces are clean and the supporting plane is perfectly flat.

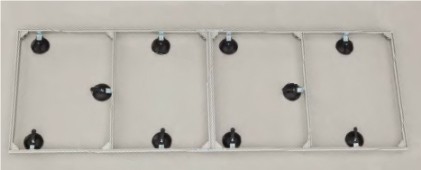

Manual systems handlig with suckers

To easer moving the 1000×3000 mm and FULL SIZE slabs (Big One 3+), especially when they are fragile due to holes or openings, and to ease use on vertical surfaces, a framework with suckers (EASY FRAME system) is available on request according to the pricelist. Always check that the suckers are properly attached before moving the slab. The frame measures 800×2400 mm and is comprised of two 1200 mm parts. Both are quick to assemble and can be used individually to install sizes smaller than 2400 mm. The suckers are positioned on sliding profiles that allow them to slide, making it possible to create different sizes. There are products on the market that are suitable for handling slabs with thickness greater 3+. The product Easy Frame cannot be used for surfaces with a textured finish.